What is LDPE (Low-Density Polyethylene)? It’s a lightweight, flexible plastic widely used in packaging for its durability, transparency, and moisture resistance. Commonly found in products like plastic bags, shrink wraps, and food packaging, LDPE offers a cost-effective solution for various applications.

Looking to source LDPE packaging? Get in touch with BN Pack for a quote and explore our high-quality flexible packaging options tailored to your needs.

What is LDPE (Low Density Polyethylene)?

Low-Density Polyethylene (LDPE) is a thermoplastic polymer made from polymerized ethylene monomers. It features a branched molecular structure, giving it flexibility and a low-density arrangement. LDPE is lightweight, flexible, and resistant to moisture and chemicals, making it ideal for packaging.

Compared to High-Density Polyethylene (HDPE) and Linear Low-Density Polyethylene (LLDPE), LDPE is softer and more flexible, with better clarity and less strength.

Why LDPE is Ideal for Coffee Packaging?

Lightweight and Flexible Nature of LDPE

LDPE’s lightweight, flexible properties make it perfect for coffee packaging. It allows manufacturers to design various pouch sizes and shapes while maintaining strength. The flexibility of LDPE helps prevent breakage or damage during transport, ensuring coffee bags remain intact. Additionally, it can be easily molded into stand-up pouches, providing convenience for consumers.

Durability and Strength for Protecting Coffee from External Factors

LDPE offers exceptional durability, providing a protective barrier against physical damage, punctures, and abrasions. Its strong molecular structure ensures that coffee remains safe during handling and shipping. The material prevents contamination, shielding the coffee from external factors like dirt, air, and tampering, ensuring the product reaches consumers in pristine condition.

Moisture Resistance for Preserving Freshness

Moisture resistance is one of the key reasons LDPE is ideal for coffee packaging. The material effectively prevents moisture from entering, which helps maintain the coffee’s freshness, aroma, and flavor. LDPE’s moisture barrier is critical in preventing the coffee from absorbing humidity, which could affect its quality, making it an excellent choice for long-term storage.

Transparency for Showcasing the Product

LDPE provides excellent clarity, making it ideal for showcasing the coffee inside. Coffee roasters and brands can take advantage of LDPE’s transparency to display the quality of their product, enticing consumers with a clear view of the coffee beans or grounds. This visual appeal is essential for marketing, creating a direct connection between the consumer and the product.

Cost-Effectiveness in Packaging Solutions

LDPE is a cost-effective material for coffee packaging, offering manufacturers a budget-friendly solution without compromising quality. Its low production cost, combined with its strength and flexibility, makes it an ideal choice for bulk coffee packaging. With LDPE, businesses can achieve high-quality packaging at a competitive price point, ensuring profitability while maintaining product integrity.

How Similar Is LDPE To Traditional Plastic?

LDPE (Low-Density Polyethylene) is a thermoplastic known for being thin, lightweight, and flexible, with the ability to withstand temperatures up to 80°C. While its tensile strength is lower than high-density polyethylene (HDPE), LDPE is more resilient, making it an ideal material for packaging that requires flexibility.

It is commonly used in films for packaging, but also in products like plastic bags, tubing, and wash bottles. What sets LDPE apart from traditional plastics is its ease and affordability of reuse and recycling.

Unlike materials like polylactic acid (PLA) or kraft paper, LDPE decomposes at a similar rate to conventional plastics. However, it is considered more eco-friendly when recycled due to the absence of harmful toxins.

Why Should Roasters Consider Using LDPE For Packaging?

In recent years, the specialty coffee industry has made notable progress in reducing plastic usage, particularly with a focus on customer consumption of plastic cups and straws. However, roasters are also feeling growing pressure to minimize their environmental impact.

Jo West, from The Coffee Roasters, a UK-based specialty coffee roaster, highlights in a blog post that roasters must adopt more eco-friendly packaging and selling practices, regardless of their output size. “Respect for the environment is now a top priority for coffee roasters, whether they’re large corporations or small startups,” she states.

It’s evident that coffee packaging plays a key role in promoting environmental sustainability. However, transitioning from conventional plastics to alternative materials can be challenging. Some options may come with higher costs or fail to protect coffee as effectively.

LDPE provides a solid solution for roasters looking to reduce plastic use without overhauling their business operations. It offers similar benefits to traditional plastics, such as a long shelf life, but is fully recyclable and reusable. Specialty coffee roasters switching to LDPE packaging see it as a way to preserve coffee quality while making a tangible commitment to sustainability.

What is LDPE Used in Coffee Packaging?

Use of LDPE in Coffee Bags, Pouches, and Wraps

LDPE is widely used in coffee packaging due to its flexibility, durability, and protective qualities. It’s commonly found in coffee bags, pouches, and wraps, offering a lightweight yet strong solution for packaging.

LDPE helps preserve the coffee’s flavor and aroma by providing a protective barrier against external elements. Its versatile nature allows for easy customization to fit various sizes and packaging designs, meeting diverse consumer needs.

Stand-Up Pouches, Vacuum-Sealed Bags, and Resealable Coffee Bags

LDPE is an excellent choice for stand-up pouches, vacuum-sealed bags, and resealable coffee bags. The material’s ability to maintain shape and structure makes it ideal for stand-up pouches, which offer enhanced shelf visibility.

Its strength and flexibility ensure that vacuum-sealed bags maintain an airtight seal, preserving freshness, while resealable bags provide convenience and reusability for consumers.

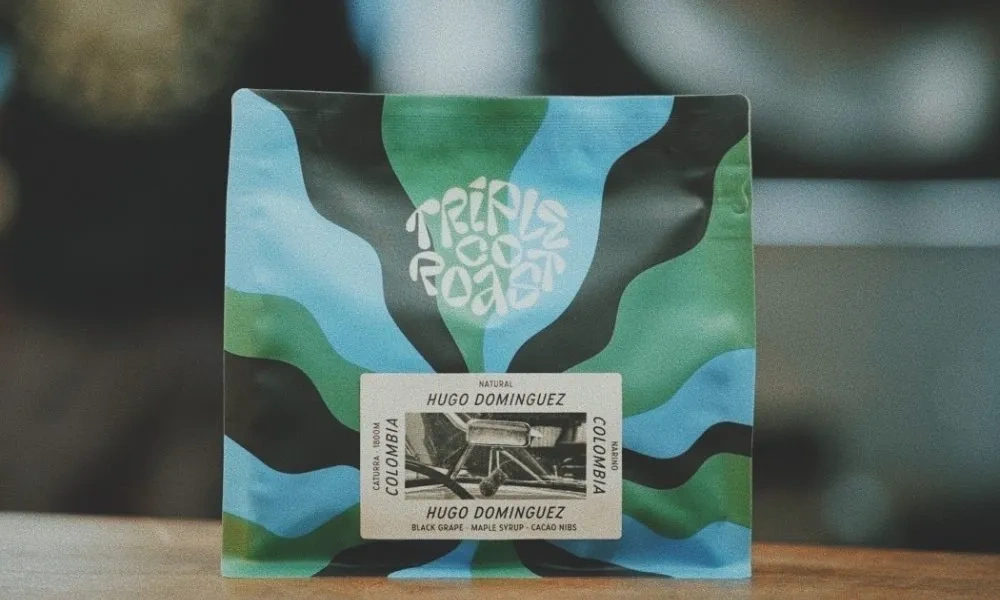

Printing Options on LDPE Coffee Packaging

One of the standout features of LDPE is its ability to support high-quality printing, which is essential for coffee packaging branding. Coffee roasters can take full advantage of LDPE’s clarity and smooth surface to print intricate designs, logos, and product information.

This allows brands to create eye-catching packaging that not only protects the coffee but also enhances its marketability on store shelves.

Multi-Layer LDPE Packaging

LDPE is often used in multi-layer packaging to provide enhanced protection for coffee. When combined with other materials such as aluminum or polyester, LDPE helps create a strong barrier against moisture, air, and light, which are all factors that can compromise the quality of the coffee.

This multi-layer approach ensures long-lasting freshness, preserves flavor, and safeguards the coffee from external contamination, making it an ideal choice for premium coffee brands.

Sustainability of LDPE in Coffee Packaging

Recycling Potential of LDPE

LDPE is a recyclable material, though its recycling potential depends on regional facilities and infrastructure. In areas where LDPE can be properly recycled, it offers a more sustainable option compared to single-use plastics.

Recycled LDPE can be repurposed into products like bins, flooring, or even new packaging. However, the efficiency of LDPE recycling is dependent on local collection and processing systems, limiting its widespread impact.

Comparison to Other Materials

Compared to other common packaging materials, such as polylactic acid (PLA) or kraft paper, LDPE has a relatively lower environmental impact, especially when considering its recyclability.

Unlike PLA, which can require industrial composting, LDPE is more widely recyclable and does not release harmful chemicals during the recycling process. Its durability also means it’s less likely to contribute to waste in landfills when recycled appropriately, offering a more sustainable alternative to many traditional plastics.

Innovations in Eco-Friendly LDPE Options

Recent innovations in LDPE packaging are aimed at enhancing its environmental sustainability. One such innovation is biodegradable coatings that can be applied to LDPE to make it more eco-friendly.

These coatings break down more easily in landfills, reducing its overall environmental footprint. Some manufacturers are exploring the use of renewable resources in the production of LDPE, further improving its sustainability and aligning it with eco-conscious packaging trends.

Making LDPE Packaging Work

Before opting for LDPE packaging, roasters should ensure customers know where to recycle their empty coffee bags.

For example, Common Coffee Roasters in Fife, Scotland, transitioned from omni-degradable packaging to LDPE bags. Their customers can recycle the empty bags by placing them in designated bins at local supermarkets.

Similarly, Modern Standards Coffee Roasters in the UK uses LDPE in their packaging and has implemented an innovative collection program. Customers can return used bags for a discount on future purchases. Once enough bags are collected, they’re sent to a specialized recycling facility where the bags are transformed into pellets and molded into recycled plastic products.

While plastic has faced criticism over the years, not all plastics are equal. LDPE provides coffee roasters with the reliability of traditional plastics but with a reduced environmental impact.

Conclusion

Understanding what LDPE (Low-Density Polyethylene) is and its benefits is crucial for businesses looking to enhance their packaging solutions. LDPE offers flexibility, durability, and recyclability, making it an ideal choice for various industries, including coffee packaging.

At BN Pack, we offer a range of materials for specialty coffee packaging solutions, and can help you decide on the perfect option for your business. Our experts can assist in selecting the ideal materials for your packaging needs, along with options for branding, degassing during transit, and sealing.

To find out more information about LDPE packaging for your coffee business, get in touch with our team.

FAQ

Is LDPE recyclable?

Yes, LDPE is recyclable, but its recyclability depends on the availability of recycling facilities in your region. Many areas have specific programs for recycling LDPE products like bags and packaging. Always check local guidelines to see where you can properly dispose of LDPE materials for recycling.

How are HDPE and LDPE different?

HDPE (High-Density Polyethylene) and LDPE (Low-Density Polyethylene) differ primarily in their molecular structure. HDPE has a more rigid and dense structure, making it stronger and more durable, while LDPE is more flexible, lightweight, and less dense. This difference results in HDPE being used for products like milk jugs and LDPE for bags and films.

What is LDPE plastic?

LDPE plastic is a thermoplastic made from polymerizing ethylene monomers. It has a low-density molecular structure, making it lightweight, flexible, and resistant to impacts. LDPE is commonly used for producing plastic bags, wraps, and various flexible packaging products due to its versatility.

Is LDPE food safe?

Yes, LDPE is generally considered food-safe. It is commonly used in food packaging like bread bags, produce bags, and wraps. LDPE does not leach harmful chemicals when in contact with food, making it a safe option for food storage and packaging, though it’s always important to verify specific product certifications for food safety.

What does LDPE stand for?

LDPE stands for Low-Density Polyethylene. It refers to a type of plastic with a low-density molecular structure, offering flexibility and resilience. LDPE is used in a variety of applications, including flexible packaging and plastic products.

What is LDPE used for?

LDPE is used for a wide range of applications, primarily in flexible packaging like plastic bags, wraps, and pouches. It’s also used for producing shrink films, containers, and some household products. LDPE’s flexibility, durability, and recyclability make it ideal for packaging and other consumer goods.

What is the difference between LDPE and LLDPE?

LDPE and LLDPE (Linear Low-Density Polyethylene) differ in their molecular structure. LDPE has a highly branched structure, which gives it more flexibility but lower strength. LLDPE has a linear structure with short branches, offering greater strength and impact resistance, making it suitable for applications requiring higher durability.

What polymer parameter was investigated with LDPE and HDPE?

Researchers commonly investigate the tensile strength, melting point, and density of LDPE and HDPE. These parameters help determine their suitability for different applications. LDPE generally has a lower tensile strength and density, while HDPE is stronger and more rigid, allowing it to withstand harsher conditions.

What topology did LDPE and HDPE exhibit?

LDPE exhibits a branched polymer topology, leading to a less crystalline and more flexible structure. HDPE, on the other hand, exhibits a more linear polymer topology, which results in a more crystalline, rigid, and stronger material. These structural differences significantly impact their physical properties.

Are LDPE bags recyclable?

Yes, LDPE bags are recyclable, but only in regions with the necessary recycling facilities. They can be dropped off at designated recycling bins, particularly in grocery stores that offer recycling programs. Always check local recycling guidelines to ensure proper disposal.

Can I recycle LDPE?

Yes, you can recycle LDPE, but it depends on local recycling programs. Many communities accept LDPE for recycling, particularly products like bags and packaging films. Make sure to separate LDPE from other materials and check local recycling programs for proper disposal.

Does LDPE contain BPA?

No, LDPE does not contain Bisphenol A (BPA). Unlike some other plastics, LDPE is not made using BPA. It is generally considered safe for food contact and does not leach harmful chemicals under typical use.

Does LDPE contain PFAS?

No, LDPE does not typically contain per- and polyfluoroalkyl substances (PFAS). LDPE is made from ethylene monomers and does not involve the use of PFAS chemicals. It is regarded as a safer alternative to other plastic materials that might contain harmful substances.

How is LDPE made?

LDPE is made through the polymerization of ethylene gas under high pressure and temperature. The process results in a polymer with a branched molecular structure, which gives LDPE its flexibility, low-density characteristics, and wide range of uses in packaging and consumer goods.