As environmental sustainability becomes a global priority, the packaging industry is undergoing a transformative shift. One of the most prominent innovations driving this change is the adoption of PCR packaging. PCR stands for Post-Consumer Recycled, a term that is increasingly found in product descriptions, corporate sustainability reports, and packaging specifications.

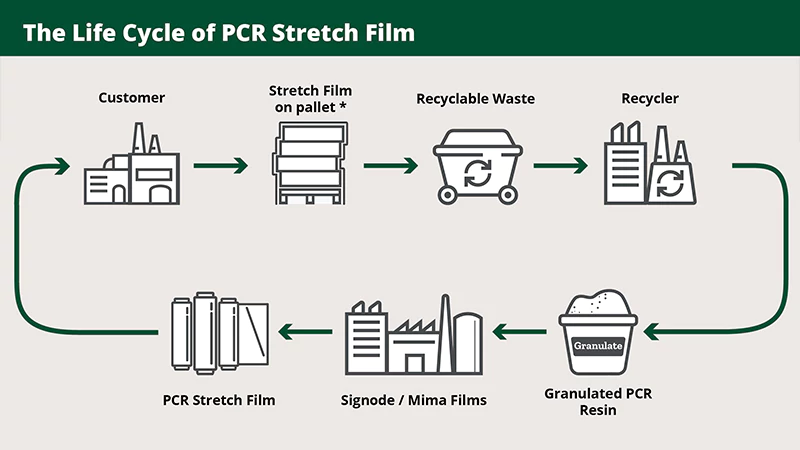

At its core, PCR packaging is made from recycled plastic materials that have already fulfilled their initial purpose in consumer products. These materials are collected, processed, and repurposed into new packaging without returning to the raw plastic production stage. This circular approach significantly reduces environmental impact and helps combat the global plastic waste crisis.

What Does PCR Stand for in Packaging?

PCR in packaging refers specifically to “Post-Consumer Recycled” materials. These are plastics that have been used and discarded by consumers, collected through recycling programs, and transformed into new packaging products. Unlike pre-consumer recycled materials—which come from waste generated during manufacturing—post-consumer recycled materials originate from end-user products. Think of used milk bottles, detergent containers, or food-grade plastic wraps. Once these items are used and discarded responsibly, they can be collected, sorted, cleaned, and processed into raw materials for new packaging.

The term PCR emphasizes that the plastic has completed its intended lifecycle in the hands of a consumer. This distinguishes it from other types of recycled content and highlights its role in closing the loop of the product life cycle. For environmentally conscious brands, using PCR material allows them to communicate a strong commitment to sustainability while reducing their carbon footprint.

From an environmental standpoint, PCR packaging helps reduce the dependency on fossil fuel-based virgin plastic. Since producing new plastic is energy-intensive and harmful to ecosystems, using recycled content makes packaging significantly more sustainable. Governments and eco-certification programs increasingly favor or mandate the use of PCR, making it a cornerstone of green manufacturing strategies.

How Is PCR Used?

PCR materials are now widely integrated across various sectors of the packaging industry. From food and beverage to cosmetics, electronics, and household items, businesses are shifting to PCR as a means to meet both regulatory demands and consumer expectations. One of the most common applications is in flexible packaging, such as pouches and bags. For example, BN PACK incorporates PCR materials into coffee bags and food pouches, combining sustainability with durability and aesthetic appeal.

Moreover, PCR plastic is utilized in sturdy packaging such as bottles and jars, which uphold durability and see-through properties while providing an environmentally friendly advantage. Progress is also being made in the development of food-grade PCR plastic, but it must adhere to stringent regulations to guarantee the safety of consumers.

A key use of PCR is in secondary and tertiary packaging solutions, including mailers, wrapping materials, and outer boxes. Although these packaging components may not directly touch food products, incorporating PCR into these layers plays a substantial role in minimizing plastic waste

can tailor PCR packaging to meet specific aesthetic and functional requirements, of finishes, from high-gloss to matte, and incorporating advanced barrier properties. This customized approach enables PCR packaging to match the performance of virgin plastic, but with a significantly reduced environmental impact.

How Is PCR Plastic Made?

The manufacturing process of PCR plastic involves several technical stages, all designed to ensure cleanliness, safety, and functional quality. First, post-consumer plastic waste is collected through curbside recycling programs or commercial recycling centers. These materials may include bottles, containers, and plastic films, all of which are sorted by resin type and color.

After sorting, the plastics are subjected to thorough cleaning to remove contaminants such as labels, food residues, and adhesives. This step is critical, especially for packaging intended for food contact. Cleaned plastics are then shredded into flakes and sometimes pelletized through melting and extrusion processes. These recycled pellets can then be incorporated into the manufacturing of new packaging products.

Here is a simplified overview of the PCR production process:

| Stage | Description |

|---|---|

| Collection | Gathering post-consumer plastic waste through recycling programs |

| Sorting & Cleaning | Removing contaminants and separating by type and color |

| Shredding | Cutting plastics into flakes or granules |

| Melting & Pelletizing | Converting flakes into usable plastic pellets |

| Reuse in Packaging | Formulating new packaging materials using the recycled pellets |

This process helps save energy, reduce landfill use, and limit environmental degradation. PCR plastic may also be blended with virgin resin to improve strength or clarity, offering a balance between sustainability and performance.

What Are the Benefits of PCR Plastic?

Using PCR plastic provides a host of environmental and economic advantages. Most importantly, it significantly reduces the need for virgin plastic production, which in turn decreases greenhouse gas emissions and fossil fuel consumption. By extending the lifecycle of plastic materials, PCR helps promote a circular economy, keeping valuable resources in use for longer.

From a corporate standpoint, using PCR can enhance brand reputation. Consumers are increasingly favoring products that reflect environmental responsibility. In competitive sectors like food and beverage or personal care, highlighting PCR content can provide a decisive advantage on store shelves and online marketplaces.

Another key benefit is compliance with evolving environmental regulations. Many governments and international bodies are now mandating minimum recycled content in packaging. Companies that embrace PCR early are better positioned to meet these standards and avoid costly penalties or supply chain disruptions.

While cost used to be a barrier, the rising demand and improved production efficiencies are making PCR more economically viable. In some markets, the cost of recycled resin is approaching parity with virgin resin, making the transition not only sustainable but also commercially sound.

Recommended PCR Bags

PCR Packaging Supplier

As demand for PCR packaging grows, the role of reliable suppliers becomes increasingly important. A qualified PCR packaging supplier must not only provide materials that meet functional and aesthetic requirements but also ensure compliance with food safety and environmental regulations.

BN PACK, for instance, is a professional supplier specializing in coffee packaging, food pouches, and environmentally friendly bags. With capabilities in recyclable, biodegradable, and compostable packaging, we now incorporate PCR materials into our offerings to help clients meet sustainability goals without compromising quality.

When choosing a PCR packaging supplier, businesses should evaluate experience, material certifications, production capabilities, and the supplier’s commitment to innovation. Transparency regarding PCR content percentages and supply chain traceability is also crucial in maintaining credibility and customer trust.

PCR Plastic Packaging Market

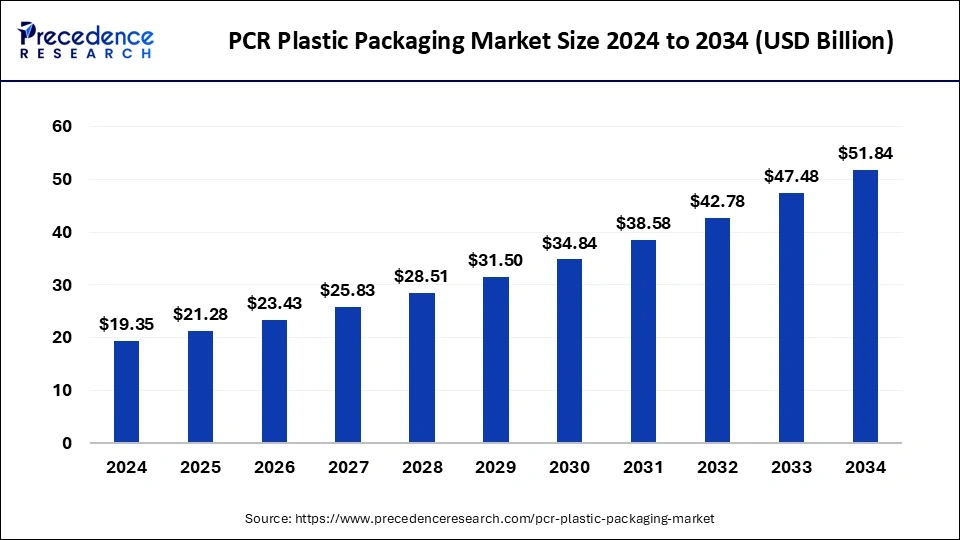

The global market for PCR plastic packaging is expanding rapidly. According to industry research, the U.S. PCR plastic packaging market was valued at USD 6.23 billion in 2024 and is expected to reach approximately USD 15.89 billion by 2034, growing at a compound annual growth rate (CAGR) of 9.86%. Stricter environmental regulations, increased consumer awareness, and technological improvements in recycling processes drive this growth.

Industries leading this growth include food and beverages, healthcare, cosmetics, and e-commerce. Brands in these sectors are increasingly investing in sustainable packaging innovations to stay competitive and comply with regulatory pressures. As the infrastructure for recycling and processing continues to improve, PCR will become an even more dominant material in the packaging industry.

BN PACK is proud to be part of this movement by offering PCR-based solutions to global customers. Our clients trust us not only for product quality but also for our commitment to environmental responsibility and forward-thinking manufacturing.

Conclusion

PCR packaging is no longer a niche option—it is rapidly becoming the new standard in sustainable packaging. By reducing the need for virgin plastic, lowering carbon emissions, and promoting a circular economy, PCR packaging represents a powerful tool for businesses aiming to align with environmental values. At BN PACK, we believe that sustainability and performance can go hand in hand. Whether you are looking for coffee bags, food pouches, or customizable eco-friendly solutions, integrating PCR materials into your packaging strategy is a smart and responsible move.

If you’re interested in learning more about how PCR packaging can support your brand’s sustainability journey, feel free to contact us or explore our range of packaging solutions.