Understanding mil thickness is crucial in various industries, from packaging to manufacturing. Mil, short for “millimeter,” measures the thickness of thin materials like plastic films, foils, and coatings. This measurement directly impacts a material’s durability, strength, and protective capabilities, influencing its suitability for specific applications.

In this blog, we’ll delve into the significance of mil thickness, exploring why it matters and how to accurately measure it. We’ll clarify common misconceptions and provide practical insights to help you make informed decisions when selecting materials. Whether you’re in packaging, construction, or manufacturing, grasping mil thickness is essential for quality assurance.

What Is Mil Thickness

Mil thickness refers to a unit of measurement used to specify the thickness of plastic films and bags. One mil is equal to one-thousandth of an inch (0.001 inches or 25.4 micrometers). This measurement is crucial for determining the strength and durability of plastic packaging materials. Higher mil numbers indicate thicker and more robust bags, capable of withstanding heavier loads and providing greater resistance to punctures and tears.

Understanding mil thickness is essential for selecting the appropriate plastic bags for specific applications. For example, thin mil bags are suitable for light-duty tasks like packaging clothing or produce, while thicker mil bags are necessary for heavy-duty applications such as construction materials or industrial products. Correctly specifying mil thickness ensures that the bags provide adequate protection and prevent product damage during storage and transport.

What is the Difference Between Mil and Gauge Thickness

Understanding the difference between mil and gauge thickness is crucial for accurately specifying and selecting plastic films and bags. While both terms relate to thickness, they are measured and used differently, leading to potential confusion if not properly understood.

Mil Thickness

Mil thickness is a unit of measurement that equals one-thousandth of an inch (0.001 inches or 25.4 micrometers). It’s a precise and direct measurement of the actual thickness of a plastic film or bag. This measurement is commonly used in the United States and is preferred in industries where accuracy is paramount, such as manufacturing and packaging.

Using mil thickness provides a straightforward way to specify the exact thickness required for a particular application. Higher mil numbers indicate thicker and more durable materials. This clarity is essential for ensuring that the chosen plastic film or bag can withstand the intended load and environmental conditions. It’s particularly important in heavy-duty applications, where precise thickness ensures product protection and structural integrity.

Gauge Thickness

Gauge thickness, on the other hand, is a less precise measurement and varies depending on the specific plastic material being used. It is often used interchangeably with mil, but it is not a direct measurement of inches, and it is more of a relative scale. The gauge system is more common in some international markets and in older manufacturing contexts.

Gauge thickness is often used because it is an easier number to remember, but it can lead to confusion because of the variability of the number. The gauge number does not always directly correlate to a specific inch or millimeter measurement, and different plastic materials can have different gauge-to-thickness conversions. This lack of standardization can result in errors and inconsistencies when specifying and ordering plastic films and bags.

How to Measure Mil Thickness

Accurately measuring mil thickness is essential for ensuring the quality and consistency of plastic films and bags. This measurement directly impacts the material’s strength, durability, and suitability for various applications. Understanding the proper techniques is crucial for precise results.

Step 1. Prepare the Sample

Begin by selecting a representative sample of the plastic film or bag you intend to measure. Ensure the sample is clean, free from wrinkles, and laid flat on a smooth surface. This preparation step is crucial for obtaining accurate and consistent measurements. Avoid measuring near edges or folds, as these areas may have variations in thickness.

Proper sample preparation minimizes the risk of measurement errors. Any inconsistencies in the sample, such as creases or folds, can lead to inaccurate readings. Cleanliness is also vital, as dirt or debris can interfere with the measuring instrument. This step ensures that the measurement reflects the true thickness of the material.

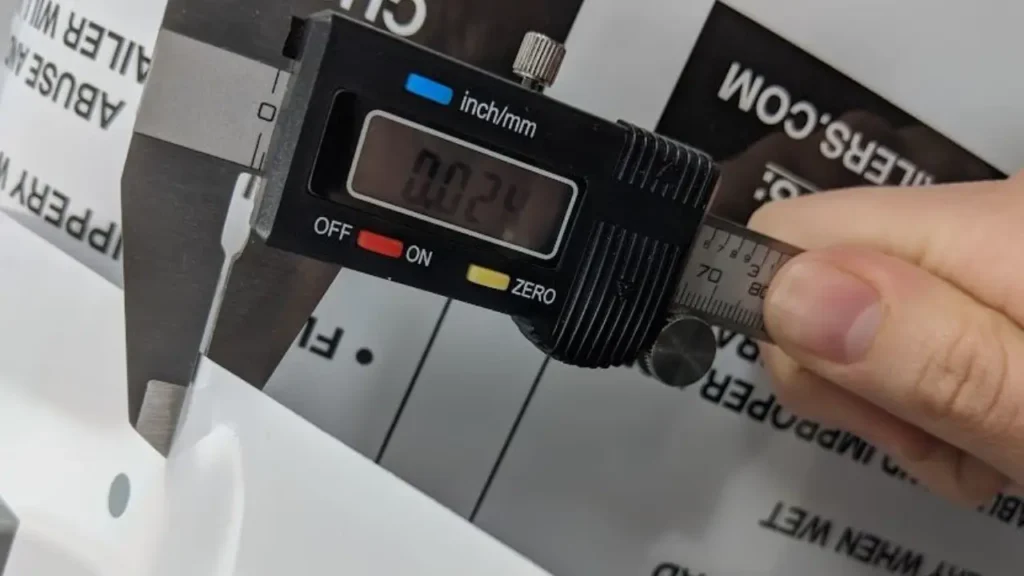

Step 2. Use a Micrometer

A micrometer is the most accurate tool for measuring mil thickness. Position the sample between the anvil and spindle of the micrometer, ensuring it is flat and aligned. Gently close the spindle until it makes contact with the sample, applying slight pressure. Read the measurement from the micrometer’s scale, typically displayed in thousandths of an inch (mils).

Using a micrometer provides precise measurements, minimizing human error. Ensure the micrometer is calibrated correctly before use to maintain accuracy. Apply consistent pressure when closing the spindle, as excessive force can compress the material and result in inaccurate readings. Record the measurement carefully to avoid errors.

Step 3. Take Multiple Readings

To ensure accuracy and consistency, take multiple readings at different points on the sample. Variations in thickness can occur across the material, so taking several measurements provides a more representative average. Calculate the average mil thickness from these readings to obtain a reliable result.

Taking multiple readings helps account for any variations in the material’s thickness. This practice is particularly important for large samples or materials with potential inconsistencies. Averaging the readings provides a more accurate representation of the material’s overall mil thickness, minimizing the impact of any localized variations.

Mil and Micron Measurements

Understanding the relationship between mil and micron measurements is crucial for accurately specifying and comparing plastic film and bag thicknesses. Both units are used to express thickness, but they operate on different scales.

Mil Measurements

Mil measurements are commonly used in the United States and represent one-thousandth of an inch (0.001 inches). This unit provides a straightforward and precise way to specify the thickness of plastic films and bags. Higher mil numbers indicate thicker and more durable materials. Mil thickness is particularly important in industries where accuracy is paramount, such as manufacturing and packaging, ensuring that the chosen material meets specific performance requirements.

Using mil measurements allows for clear and consistent communication regarding material thickness. This is essential for ensuring that the chosen plastic film or bag can withstand the intended load and environmental conditions. It simplifies the selection process, enabling users to accurately compare different materials and choose the most suitable option for their needs.

Micron Measurements

Micron measurements, also known as micrometers, are used internationally and represent one-millionth of a meter (0.000001 meters). This unit is part of the metric system and is commonly used in scientific and industrial applications worldwide. Micron measurements are often preferred in countries using the metric system or in industries that require precise measurements for thin materials.

Converting between mil and micron measurements is straightforward, with one mil equaling approximately 25.4 microns. This conversion allows for easy comparison and standardization across different regions and industries. Using micron measurements provides a high degree of precision, particularly when dealing with very thin films or materials where even small variations in thickness can significantly impact performance.

How Thick is 2 Mil Plastic

Two mil plastic refers to a plastic material with a thickness of 0.002 inches, or two-thousandths of an inch (approximately 50.8 micrometers). This thickness is considered relatively thin and is commonly used for light to medium-duty applications. Plastic bags and films of this thickness offer moderate protection against punctures and tears, making them suitable for various packaging and storage needs.

Applications for 2 mil plastic include trash bags, produce bags, garment bags, and light-duty industrial liners. While it provides a decent level of protection, it may not be suitable for heavy or sharp objects. Understanding the specific requirements of your application is crucial in determining if 2 mil plastic is sufficient or if a thicker, more durable material is needed.

How to Choose the Right Mil

Selecting the right mil thickness for plastic bags is crucial for ensuring optimal performance and protection. This decision directly impacts the bag’s durability, strength, and suitability for specific applications. Understanding the factors that influence mil selection is essential for making informed choices.

Step 1. Consider the Application

Begin by assessing the specific application for which the plastic bags will be used. Light-duty applications, such as packaging clothing or produce, may require thinner mil bags. Medium-duty applications, like trash bags or retail packaging, typically benefit from mid-range mil thicknesses. Heavy-duty applications, such as construction debris or industrial materials, demand thicker mil bags.

Understanding the intended use of the bags helps determine the necessary level of protection and durability. Light-duty applications prioritize flexibility and cost-effectiveness, while heavy-duty applications prioritize strength and puncture resistance. Consider the weight, shape, and potential sharp edges of the items being packaged.

Step 2. Evaluate Product Weight and Sharpness

The weight and sharpness of the items being packaged significantly influence the required mil thickness. Heavier items necessitate thicker bags to prevent tearing and maintain structural integrity. Sharp or pointed items require even thicker bags to minimize the risk of punctures. Consider the potential for movement or shifting within the bag, as this can also increase stress on the material.

For light-weight, and non-sharp products, a thinner mil thickness is often sufficient. If your products are heavy, or have sharp edges, you should always select a thicker mil thickness. Ensuring the bag can withstand the product’s weight and prevent damage during handling and transport is crucial for product safety and customer satisfaction.

Step 3. Assess Environmental Conditions

Consider the environmental conditions the bags will be exposed to during storage and transport. Extreme temperatures, moisture, and exposure to chemicals can degrade plastic bags over time. Thicker mil bags offer enhanced resistance to these factors, providing added protection for sensitive or valuable items.

Evaluate the potential for abrasion or friction during transport. If the bags will be subjected to rough handling or prolonged contact with other surfaces, thicker mil bags offer greater durability. Consider the storage environment and the potential for prolonged exposure to sunlight or other degrading factors.

Step 4. Determine Cost-Effectiveness

Balance the cost of the plastic bags with the required level of protection and durability. Thicker mil bags are generally more expensive, but they offer greater strength and longevity. Evaluate the potential cost of product damage or replacement due to inadequate packaging. Select a mil thickness that provides the optimal balance of performance and affordability.

Consider the long-term cost implications of using thinner mil bags. While they may be cheaper initially, they may result in higher replacement costs due to damage or premature failure. Evaluate the overall value proposition, considering the bag’s lifespan and its ability to protect your products effectively.

Role of Poly Bag Thickness in Effective Packaging

Understanding the critical role of poly bag thickness is essential for effective packaging. The thickness of a poly bag, measured in mils, directly impacts its strength, durability, and suitability for various applications. Selecting the appropriate thickness ensures product protection, reduces waste, and optimizes packaging efficiency.

Product Protection and Durability

The thickness of a poly bag is a primary determinant of its ability to protect the contents from damage. Thicker bags offer greater resistance to punctures, tears, and abrasion, making them suitable for heavy or sharp items. This protection is crucial for maintaining product integrity during storage, transport, and handling. Inadequate thickness can lead to bag failure, resulting in product damage and potential loss.

Furthermore, thicker poly bags provide enhanced barrier properties, protecting contents from environmental factors such as moisture, dust, and chemicals. This is particularly important for sensitive products like food, pharmaceuticals, and electronics. The durability of thicker bags also extends their lifespan, reducing the need for frequent replacements and minimizing waste.

Packaging Efficiency and Cost-Effectiveness

Selecting the appropriate poly bag thickness optimizes packaging efficiency and cost-effectiveness. Thinner bags are suitable for light-duty applications, reducing material costs and minimizing waste. However, using excessively thin bags for heavy or sharp items can lead to bag failure, resulting in product damage and increased replacement costs.

Conversely, using unnecessarily thick bags for light-duty applications increases material costs without providing significant added value. A balanced approach ensures that the bag’s thickness aligns with the product’s requirements, minimizing material usage and reducing overall packaging costs. Efficient packaging also streamlines handling and storage, reducing labor costs and improving operational efficiency.

Conclusion

Understanding mil thickness is crucial for selecting the right plastic bags, ensuring optimal protection and durability. This measurement directly impacts a bag’s strength and suitability for various applications, from light packaging to heavy-duty industrial use. Accurate mil thickness specifications prevent product damage and maintain integrity.

Proper measurement techniques ensure consistency and reliability in your packaging. Incorrect mil thickness can lead to premature bag failure, resulting in product loss and customer dissatisfaction. Knowing how to measure mil thickness empowers informed purchasing decisions, aligning packaging with specific product needs.

For reliable and high-quality wholesale plastic bags with precise mil thickness, trust BN Pack. We offer a wide range of customizable options to meet your unique packaging requirements. Contact BN Pack today to discuss your needs and secure durable, dependable plastic bags for your business.