PET PE Bags & Polyethylene Packaging

Unlocking optimal product protection & shelf appeal starts with PET PE packaging. As leading flexible packaging manufacturers, we understand its versatility. This robust laminate offers superior barrier properties & clarity. Need bespoke solutions? Explore custom PET/PE packaging from BN Pack today.

Why BN Pack PET PE Packaging?

Facing the need for improved packaging, industries are turning to flexible PET/PE instead of rigid boxes, particularly for food. But what is PET/PE, and how does it meet diverse packaging needs? We’ll examine PET and PE to find out.

What is PET?

You’ll find polyethylene terephthalate, or PET, just about everywhere. This incredibly versatile plastic has become a global workhorse, serving a vast array of industries. From packaging to manufacturing, its presence is undeniable.

What makes PET so popular? It’s a powerhouse of desirable qualities: strong yet lightweight, and crystal clear. This combination makes it perfect for food storage and transport, keeping items safe and visible. But its uses don’t stop there; PET also confidently holds everything from liquid soaps to cleaning solutions.

Delving into the science, PET is born from a chemical process known as esterification. Imagine an acid, terephthalic acid, joining forces with an alcohol, ethylene glycol, under precise conditions. The result? A robust polyester, PET, the most common thermoplastic member of its family.

And here’s a crucial point: PET carries the resin identification number “1.” This simple digit signifies its recyclability, meaning it can be processed and reused multiple times, contributing to a more sustainable approach to plastics.

What is PE?

Polyethylene, a ubiquitous polymer in packaging, reigns as the world’s most prevalent plastic. Its versatility stems from its diverse forms, all built upon repeating ethylene monomers. Density dictates its classification, yielding familiar variants like HDPE, LDPE, and the focus here, LLDPE.

Linear Low-Density Polyethylene (LLDPE), specifically within the 0.915-0.925g/cm³ density range, distinguishes itself with superior tensile strength compared to LDPE. This enhancement translates to improved impact and puncture resistance, making it a favored material in packaging. Beyond this, LLDPE finds application in cable coverings, toys, buckets, and containers, showcasing its broad utility.

The film industry particularly benefits from LLDPE’s exceptional properties. Its unique combination of toughness, flexibility, and relative transparency makes it an ideal choice for various film applications. This balance of characteristics ensures both durability and visual clarity, crucial for effective packaging and other film-based products.

Common BN Pack Polyester Laminations

BN Pack can be laminated different ways depending what is necessary to the products inside the packaging bag. We can help you navigate the decision regarding which lamination is best from a basic PET/PE, or KPET/PE lamination, to enhanced laminations with EVOH, or PVDC coatings.

With so many options we have a lamination for most demanding applications from retort pouches, to a wide array of shelf stable application from FDA food, to industrial packaging. Printed or un-printed the CareClear material family of PET/PE base plastic is a great solution for products made in China and beyond. Our base BN Pack PET/PE materials are also an amazingly economical choice in comparison to most suppliers.

- PET/PE: General use clear barrier

- PET/Nylon/PE: Enhanced Moisture / water barrier and strength

- KPET/PE: PVDC coated for higher barrier

- KPET/Nylon/PE: Enhanced barrier and strength

- PET/ALox/PE: ALox specialty film

- PET/EasyPeel: Easy Peable heat sealable interior sealant layer

- BOPP/PE: For low barrier uses

PET & PE Chemical Structures

PET’s molecular structure is built from repeating ethylene terephthalate monomers.

A key structural feature is the presence of an aromatic ring, a hexagonal formation that imparts significant strength and rigidity to the polymer. This inherent stiffness translates to a higher resistance to deformation compared to many other plastic materials.

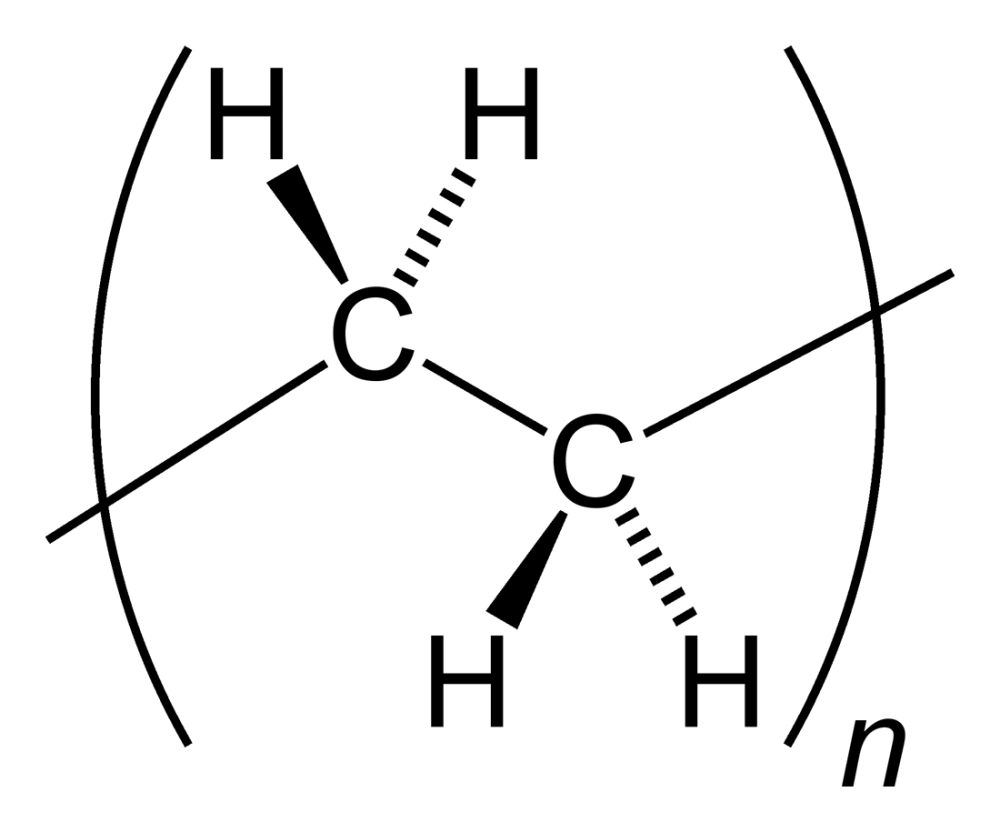

Polyethylene, a polymer with a repeating ethylene monomer structure, possesses a specific molecular arrangement.

Its composition consists of non-polar, saturated hydrocarbons characterized by a high molecular weight. This structural feature is responsible for polyethylene’s notable chemical stability, rendering it resistant to degradation from strong acids and bases.

PET & PE Method of Production

PET’s creation hinges on esterification, a straightforward chemical reaction. This process heats ethylene glycol and terephthalic acid, transforming them into a molten substance that can be shaped according to manufacturing requirements.

Under low vacuum pressure and elevated temperatures, these components combine, initiating the formation of extended polymer chains. As the mixture thickens, these chains lengthen further. The reaction concludes upon reaching the targeted polymer chain length.

Polyethylene’s synthesis relies on ethylene polymerization, a process conducted under precise conditions and catalyzed by specific substances.

The production of PE film commonly utilizes “blown film extrusion,” a multi-stage technique also applicable to other polymers. This method incorporates an “extruder,” a key piece of equipment in the manufacturing process.

Why BN Pack over other polymers?

Numerous polymers are created daily, each finding niche applications across diverse sectors. Yet, within the realm of thin-film applications, PET and PE have achieved remarkable prominence. This dominance has sparked widespread curiosity regarding the factors contributing to their prevalence in this specific field.

PET's dominance in thin-film applications stems from its exceptional mechanical strength, surpassing that of many other plastics. Furthermore, its superior electrical properties render it an ideal substrate for thin-film solar cells and a valuable material in semiconductor manufacturing.

PET plastic exhibits minimal moisture absorption and notable heat resistance, maintaining its physical integrity across a broad temperature spectrum. Additionally, its exceptional gas barrier properties make it particularly suitable for packaging films where extended shelf life is essential.

PE exhibits good tape adhesion, making it a solid option as a protection in certain applications like waterproofing and painting.

Are You Looking for a Trustworthy Pet Pe Packaging Supplier?

With more than 10 years of experience, we offer customized designs with the fastest delivery. Contact our customer service team to know our plastic minimum order quantities.

What Type of Coatings Can Be Applied to BN Pack Packaging?

Both PET and PE offer a range of valuable characteristics suitable for diverse applications, including storage. However, PET’s barrier properties, particularly against oxygen, are insufficient for certain perishable food and beverage items.

To address this limitation, PET’s barrier performance can be enhanced through coatings such as Nylon 6 and vinyl-alcohol. These coatings are applied to a single surface of a monolayer polyester film.

PET Laminated to PE

PET/PE film, a composite material, consists of a PET film layer bonded to a thin PE film layer. This combination comes in various forms, tailored to specific applications, including coatings with EVOH, PVDC (KPET), and haptic coatings such as soft touch.

Distinct from other polymers, PET/PE film provides an exceptional barrier against moisture and gases. Its air- and water-tight properties make it a prime choice for storage bags designed for perishable goods with short shelf lives.

Common Applications and Uses of PET/PE Film

PET/PE film is commonly employed in the packaging industry. Some of its applications include:

- Food and beverage packaging.

- Thermoforming process for multiple packaging applications.

- Pharmaceutical and medical products packaging.

Comparison of Bn Pack to Other Barrier Materials

PET/PE film is better suited to packaging certain substances over other barriers due to its properties. PET/PE film, which is a double layer barrier, has better optical transparency and is lightweight compared to other barriers like metals.

It is a transparent material that offers an economical clear barrier. It is also chemically inactive and will not interact with your product in any way, even if it’s stored for days.

Looking for a Win-Win Business Relationship?

We will always be your reliable pet pe packaing partner to work with!

Please feel free to contact us now if you are interested in our packaging and bags.

PET PE: Your Ultimate Guide

1) What are the fundamental differences between PET and PE?

PET (Polyethylene Terephthalate) and PE (Polyethylene) are both polymers, but they differ significantly in their chemical structure and properties. PET is known for its high tensile strength, clarity, and gas barrier properties, making it ideal for beverage bottles and rigid containers. Its molecular structure, featuring aromatic rings, contributes to its stiffness. PE, on the other hand, is more flexible and impact-resistant, and it comes in various densities (LDPE, HDPE, LLDPE), each with distinct characteristics.

PE’s simple hydrocarbon structure results in a more pliable material, well-suited for films, bags, and flexible packaging. PET’s more complex structure provides a higher level of rigidity and also much better gas barrier properties. This means that PET is much better at keeping gasses like oxygen from getting to the products stored inside of it. This is why PET is used for soda bottles.

2) Which type of packaging is more suitable for food storage, PET or PE?

PET is often preferred for food and beverage packaging that requires a strong barrier against oxygen and moisture, such as carbonated drinks, juices, and oils. Its clarity also allows consumers to see the product inside. However, PET’s oxygen barrier properties can be limited for extremely sensitive products.

PE, particularly high-density polyethylene (HDPE), is commonly used for milk jugs, food storage containers, and flexible films. Low-density polyethylene (LDPE) is ideal for bags and wraps. The choice depends on the specific food product’s requirements. For example, PE films are excellent for preventing moisture loss in produce, while PET is better for maintaining the carbonation of beverages.

3) Is PET or PE packaging recyclable?

Both PET and PE are recyclable, but the recycling processes and rates can vary. PET is widely recycled, and recycled PET (rPET) is often used to create new bottles and containers. PE recycling rates vary depending on the type of PE and local recycling infrastructure.

It is important to check local recycling guidelines, as not all PE types are accepted in every recycling program. Recycling both PET and PE helps reduce plastic waste and conserve resources. However, it is also important to note that the recycling process itself has an environmental impact.

4) What are the advantages of using PET/PE laminated films?

PET/PE laminates combine the strength and barrier properties of PET with the flexibility and sealing properties of PE. This combination creates a versatile material suitable for a wide range of packaging applications.

These laminates offer excellent moisture and gas barrier properties, making them ideal for packaging perishable goods, snacks, and other products that require extended shelf life. The combination of the two materials makes for a very strong and durable packaging material.

5) Are PET and PE packaging safe for food contact?

Yes, both PET and PE are generally considered safe for food contact. They are approved by regulatory agencies like the FDA for use in food and beverage packaging.

It’s important to use these materials according to their intended purpose and avoid exposing them to excessive heat, which could potentially cause the release of undesirable substances. Also, reusing single use bottles over very long periods of time is not recommended.

6) What are the heat resistance limitations of PET and PE?

PET has moderate heat resistance, but it can deform at high temperatures. It’s not typically recommended for use in microwave ovens unless specifically designed for that purpose.

PE’s heat resistance varies depending on the type. LDPE has a lower melting point, while HDPE can withstand slightly higher temperatures. Generally, PE is not suitable for high-heat applications like microwaving.

7) How do environmental conditions effect PET and PE?

both pet and PE, like most plastics degrade very slowly. Prolonged exposure to UV light will cause both types of plastic to become brittle, and can change their color. very high temperatures can cause warping.

In normal environmental conditions, PET and PE are relatively inert, however it is important to insure that proper disposal is followed. Because if littered, these plastics can last for very long periods of time, and cause harm to wildlife.

8) Can PET, or PE be used in medical applications?

Yes, both PET and PE have applications in the medical field. PET is used for items like medical implants, and some drug packaging, due to its chemical inertness.

PE, particularly HDPE, is used for medical packaging, and also some medical devices. PE is used in many disposable medical products. Ensuring sterility is vital in these medical uses, and both PET, and PE, are easily able to be sterilized.

Get Your PET PE Wholesale Now

PET PE packaging solutions offer a versatile, high-performance option for diverse industries. The synergistic blend of PET’s strength and barrier properties with PE’s flexibility and sealability creates a superior packaging material. Choosing the right PET PE combination optimizes product protection, shelf life, and consumer appeal. For custom PET/PE packaging solutions tailored to your specific needs, contact BN Pack, your trusted flexible packaging manufacturer and supplier. Let us help you elevate your brand with innovative packaging.