If you want your business to grow well, roll stock film like BN PACK’s Rolls film packaging is usually the cheapest choice when you produce a large volume of products. Packaging costs are very important as they help you set competitive prices and attract more customers.

If packaging costs are high, it becomes harder to compete.

Fluctuations in recycled material prices and supply chain issues can negatively impact your profits.

Trend | Impact on Packaging Choices |

|---|---|

Shift to Eco-Friendly Options | Brands are increasingly selecting recyclable and biodegradable materials. |

Cost-Effective Solutions and Versatility | Roll stock film attracts major brands due to its efficiency and adaptability. |

You can make better choices for your business by understanding these factors and utilizing cost-effective packaging solutions.

Quick Comparison Overview

Key Differences

When you look at roll stock film and pre-made pouches, you notice some big differences. The cost, speed, and how they fit your business as it grows are not the same. Roll stock film, like BN PACK’s Rolls film packaging, is best if you make a lot of products. You save money because you do not pay extra converter costs. You also get faster production with machines that work by themselves. This gives you more steady results.

Pre-made pouches are good if you make small batches. You can use easy machines or fill them by hand. This is helpful for small businesses or if you want to try new products. But each pouch costs more, and you need more room to store them.

Tip: If you plan to make more than 300,000 units each year, roll stock film is the best deal. If you make less, pre-made pouches might be better for you.

Here are some main things to think about:

Roll stock film costs 25% to 35% less for each unit than pre-made pouches.

Roll stock film lets you use fast, automatic machines.

Pre-made pouches are good for small amounts and many kinds of products.

Roll stock film needs less storage space.

Summary Table

Feature | Roll Stock Film (BN PACK) | Pre-Made Pouches |

|---|---|---|

Material Cost | $0.04 per unit (25-35% lower) | $0.16 per unit (higher cost) |

Production Speed | High-speed, automated | Slower, manual or semi-automatic |

Equipment Needs | VFFS/HFFS machines required | Simple machines or manual filling |

Scalability | Best for high-volume production | Best for small batches |

Storage Space | Compact rolls, less space needed | More space needed |

Consistency | High accuracy, less variation | Manual handling, more variation |

You can use this table to help you pick the right packaging for your business. If you want to grow and spend less, roll stock film is the smart pick.

Cost-Effective Solutions for Scaling

Material and Unit Costs

You want to spend less on packaging as your business grows. Roll stock film is a good way to save money when you make lots of products. You pay 30 to 50 percent less for materials than with pre-made pouches. This big savings adds up quickly when you make thousands or millions of packages.

Roll stock film used in FFS systems costs 30 to 50 percent less than pre-made pouches.

You save more when you buy bigger amounts.

Lower material costs help you give better prices to your customers.

BN PACK’s Rolls film packaging helps you keep costs down. You get strong materials and good protection without extra pouch costs. This makes roll stock film a smart pick if you want to save money and grow your business.

Equipment and Labor Investment

You need to think about machines and workers when picking packaging. Roll stock film works with automatic machines like VFFS and HFFS. These machines fill and seal packages fast. One person can run several machines at the same time. This setup lowers labor costs and helps you grow without hiring many new people.

Roll stock film systems, especially VFFS, need fewer workers, so one person can run more machines, which cuts labor costs a lot.

Pre-made pouch systems usually need two or three people for loading and checking, which makes costs go up.

A case study shows that using automated roll stock film cut labor costs by 65 percent. You get faster production and need fewer workers. This means you can spend your money on other parts of your business. Picking cost-effective solutions like BN PACK’s Rolls film packaging gives you better value over time.

Packaging Waste and Efficiency

You want to waste less and get more from your packaging. Roll stock film helps you do this. Automatic machines use just enough material for each package. This lowers waste and keeps your work area neat and efficient.

Here is a quick look at how roll stock film compares to pre-made pouches:

Feature | Roll Stock Film | Pre-Made Pouches |

|---|---|---|

Material Cost | Lower unit cost, good for big batches | Higher unit cost, better for small |

Production Efficiency | High efficiency with FFS machines | Semi-automatic, less efficient |

Material Waste | Less waste from automatic machines | More waste from manual work |

You can see roll stock film helps you save money by cutting waste and making work faster. You spend less on materials and workers, and you finish more products in less time. This helps your business grow and keeps your packaging strong.

Tip: If you want to grow your business and save money, choose cost-effective solutions like BN PACK’s Rolls film packaging. You will see better profits and faster production.

Operational Efficiency with BN PACK Rolls Film Packaging

Production Speed and Throughput

You want your packaging line to move fast and handle more products as your business grows. BN PACK Rolls film packaging lets you do this with high-speed machines. These machines can fill and seal bags much faster than pre-made pouch systems. You can see the difference in the table below:

Machine Type / Configuration | Typical Speed (bags per minute) |

|---|---|

6-station premade pouch machine | 12 to 25 |

8-station premade pouch machine | 25 to 45 |

Medium-high-speed rotary premade pouch | Up to 50 |

Large bag premade pouch machine | Up to 40 |

High-speed rotary premade pouch | Up to 200 |

With roll stock film, you can reach speeds up to 200 bags per minute. This means you finish orders faster and keep up with demand during busy seasons.

Automation and Integration

You can connect BN PACK Rolls film packaging to advanced machines that work automatically. These machines form, fill, and seal each package without stopping. You need fewer workers to run the line, which saves money and reduces mistakes. BN PACK uses rapid prototyping and agile manufacturing to help you launch new products quickly. You can get samples in 72 hours and bulk orders in just 15 days. This fast process helps you stay ahead of your competition.

Note: BN PACK uses 12 digital printers for short runs and 8 gravure printing lines for big orders. You get high-quality packaging, no matter the size of your project.

Storage and Logistics

You save space and money when you use roll stock film. Rolls take up less room than boxes of pre-made pouches. You can store more material in your warehouse and reduce shipping costs. Roll stock film lets you make pouches on demand, so you do not need to keep a large inventory. This lowers waste and keeps your operation lean. Faster packaging also means you move products out the door quickly, which helps your business grow.

BN PACK’s focus on Cost-Effective Solutions and sustainability gives you an edge. You get efficient packaging that meets customer needs and supports your growth.

Scalability and Business Fit

When to Choose Roll Stock Film

Pick roll stock film if you want your business to grow. It works best for making lots of products at once. This packaging is good for snacks, fresh produce, and medical devices. The table below shows which businesses and products use roll stock film most:

Business Size | Product Types |

|---|---|

Large-scale | Snacks, fresh produce, medical devices |

Small-scale | Chips, candy, cosmetics, small electronics |

Roll stock film helps you save money when you make many packages. You can use machines that fill and seal packages fast. This way, you spend less and waste less. You also get bright pictures and special barriers to keep things fresh. If you want your brand to grow and reach more people, roll stock film is a smart pick.

When Pre-made Pouches Make Sense

Pre-made pouches are good for small batches or testing new products. You do not need big machines for these pouches. You can fill and seal them by hand or with simple tools. Pre-made pouches are easy and flexible. You can switch between products and try new designs quickly. This makes them great for short runs or seasonal items.

Advantage | Description |

|---|---|

Convenience | Ready to fill and seal, no big machines needed |

Flexibility | Easy to change for different products or looks |

Customization | Fun design choices for special branding |

If you want to try a new product or keep less stock, pre-made pouches help you stay quick and ready.

Product Variety and Customization

You need packaging that fits your product and your brand’s style. BN PACK gives you lots of ways to customize. You can get samples and prototypes the same day to test ideas fast. The company uses advanced printing for sharp graphics and logos. You can pick recyclable, compostable, or biodegradable films to help the planet.

Feature | Description |

|---|---|

Same-day samples and prototypes | Try and change products quickly |

Wide range of customization | Special choices for how your product looks and works |

Advanced printing technology | Sharp, custom packaging |

Speed and nimbleness | Fast production and shorter wait times |

Roll stock film lets you change thickness, barriers, and how it looks. You can make packaging that stands out and keeps products safe. This helps your business grow and change over time.

Tip: Pick packaging that works for you now and can grow with your business. BN PACK’s Cost-Effective Solutions and custom options help you stay ahead in any market.

Real-World ROI and Growth Impact

Cost Comparison at Scale

When your business gets bigger, packaging costs matter a lot. If you use roll stock film, you save money fast. For example, packaging 1 million units can save you $120,000. This is compared to using pre-made pouches. Many big brands pick BN PACK’s Rolls film packaging for this reason. They pay less for each package and make products faster. You can use the money you save for marketing or new products. You can also buy better equipment. This helps your business grow quickly.

Transitioning to Automation

Switching to automated roll stock film systems helps a lot. You get many good changes:

Automation makes work faster and costs less.

Machines do the work, so there are fewer mistakes.

Quality control gets better, so you waste less.

Managing inventory is easier, which saves time and money.

Machines know when they need fixing, so you avoid long stops.

BN PACK helped brands like Walmart and Member’s Mark use automated packaging. These companies now make more products with less work. You can do the same and see great results.

Long-Term Profitability

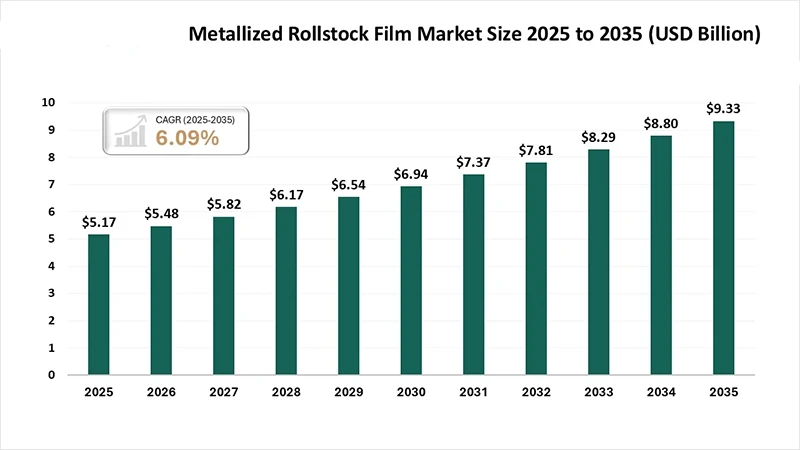

Roll stock film packaging helps your business grow for a long time. The market for roll stock film grows about 4-5% every year since 2015. Experts think it will be worth $30 billion by 2030. New technology and higher incomes help this growth. Eco-friendly solutions also make it grow. Even in hard times, companies using roll stock film did well. By 2022, they had record sales. When you choose BN PACK, you join smart brands that use cost-effective packaging to stay ahead.

Tip: If you invest in roll stock film now, your business can keep making money and growing for years.

You now know roll stock film is good for growing your business. It costs less and gives you more choices for making lots of products. Pre-made pouches are easy to use and let you change designs fast for small batches.

Roll stock film is great for big orders and custom branding.

Pre-made pouches work well for small, flexible projects.

If you need help, BN PACK can support you. Here is what they offer:

Feature | Details |

|---|---|

Experience | More than 22 years in flexible packaging |

Custom Solutions | Biodegradable, child-resistant, vacuum bags |

Certifications | ISO 9001, US FDA |

Production Capacity | 1.2 million bags made each day |

Global Reach | Over 100 countries get their products |

Pick the best packaging for your business growth. BN PACK helps you grow with smart and cost-saving solutions.