Color is one of the most powerful tools in packaging design: it captures attention, evokes emotion, and influences purchase decisions. In this guide, we’ll explore why color matters, the psychology behind hues, cultural and demographic factors, technical constraints of printing on various materials, and special considerations for eco‑friendly packaging.

You’ll also find real‑world case studies and actionable best practices to help BN PACK create standout, on‑brand packaging for coffee, food, and degradable or compostable bags.

The Importance of Color in Packaging

Color is the first visual cue consumers register on a shelf or website, and it can make or break a sale. High‑contrast or bold hues help products stand out in crowded retail environments, while subtle palettes can convey luxury or minimalism. In fact, up to 85 percent of consumers cite color as a primary factor in their purchase decisions, underlining its direct impact on conversion rates.

In addition, the color of the packaging generates instant brand awareness. Utilizing a trademark color on a consistent basis, such as Tiffany Blue or Coca-Cola Red, helps to establish a sense of familiarity and trust over time. Because of this consistency, BN Pack will be able to strengthen its brand equity and encourage customers to make additional purchases when it chooses its main brand colors for its coffee and food bags.

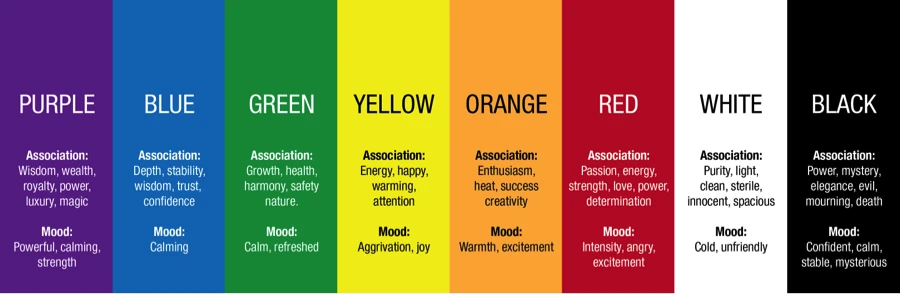

Color Psychology and Consumer Behavior

It is perfect for coffee blends or spicy snack packages because red is a color that stimulates appetite, portrays enthusiasm and desire, and so on.

A color that exudes tranquility, trust, and dependability, blue is an excellent choice for quality teas, foods that are focused on health, or hydration goods.

Green is a color that is universally linked with nature, health, and sustainability; it is well-suited for the biodegradable and compostable lines that BN Pack offers.

Brown and earth tones are obvious choices for coffee, grains, and artisanal foods because they evoke feelings of warmth, an abundance of richness, and authenticity.

There is a balance between harmony (using palettes that are complementary or comparable) and contrast in effective color schemes, which helps to lead the eye. In order to immediately draw attention to important messaging such as “100 percent compostable,” a background that is dark and espresso brown and with a bright yellow accent can be quite effective. On the other hand, a subdued foundation paired with a rich accent can indicate refinement while still drawing attention to elements that are significant.

Technical and Material Considerations

Packaging materials and printing methods have a profound impact on how colors appear in the finished product. Before finalizing your color palette, consider these factors:

Substrate Effects

- Surface Texture: Matte papers absorb light differently than glossy films. Matte kraft papers lend a soft, muted look but can make colors appear flatter, while glossy laminated films reflect light, enriching vibrancy and contrast.

- Ink Absorption: Porous materials (like uncoated kraft or certain compostable films) draw in more ink, which can lead to slight darkening or dulling of your intended shade. Non‑porous substrates (such as polyethylene or BOPP) allow ink to sit on the surface, yielding brighter, crisper color.

- Barrier Coatings and Lamination: Many food‑grade bags include barrier layers or laminates for moisture and oxygen protection. These coatings can cause subtle color shifts or glare. Always request press proofs on your exact material grade—coated or uncoated—to confirm how your palette translates.

Color Matching and Consistency

- Color Management Systems: Employ ICC profiles tailored to each substrate and printing process. This ensures your digital design’s RGB or Pantone values convert accurately to CMYK (or to specific spot inks) on press.

- Proofing and Press Checks: Schedule digital and wet‑ink proofs before full production. A spectrophotometer‑driven press check will verify that the printed color falls within an acceptable tolerance range (usually ΔE < 2).

- Printing Technologies: Different presses—flexographic, rotogravure, digital toner or inkjet—each handle color reproduction uniquely. Digital presses excel at short runs and variable data but may have limited gamut; offset and flexo handle spot colors robustly but require more setup.

- Environmental Factors: Temperature, humidity, and even ink age can subtly influence hue and dot gain. Keep pressroom conditions stable and track ink lot numbers to minimize batch‑to‑batch variation.

Color in Eco‑Friendly Packaging

Designing with sustainability in mind adds new layers of consideration to your color strategy:

Material‑Driven Color Limits

- Natural Substrates: Unbleached kraft and recycled papers carry inherent browns and flecks, which will tint overprinted hues. Account for this by selecting pigments with higher opacity or adjusting your design to embrace an earthy palette.

- Bioplastic Films: Compostable polymers (PLA, PBAT blends) often have a slight haze. Colors may read softer; vivid primaries can lose punch unless formulated specifically for that substrate.

Eco‑Ally Ink Technologies

- Water‑Based and Soy Inks: These low‑VOC options align with green messaging, yet their translucency can differ from conventional petroleum‑based inks. Conduct sample prints to dial in ink load and opacity for each hue.

- Regulatory Labeling: Certifications like “OK Compost,” “FSC,” or “BPI” require clear, legible logos. Choose accent colors that ensure these symbols stand out—white or darker tones on lighter backgrounds, or vice versa, to maintain accessibility and compliance.

Design Strategies for Sustainability Messaging

- Earth‑Tone Foundations: Lean into palettes of browns, beiges, moss greens, and muted rusts to reinforce the eco narrative.

- Vibrant Call‑Outs: Reserve brighter hues—leaf green, sunflower yellow, sky blue—as small but impactful highlights for phrases like “Recyclable” or “Certified Compostable.” This allows your eco‑message to pop without overwhelming the natural aesthetic.

- Minimalist Layouts: Let raw substrate textures and simple typography carry much of the visual weight, using color sparingly to guide the eye and emphasize critical information (e.g., flavor, weight, batch code).

Conclusion

Strategic color design is indispensable for BN PACK’s coffee, food, and eco‑friendly bags. By understanding color psychology, respecting cultural nuances, managing technical constraints, and staying true to your sustainable brand ethos, you can create packaging that not only looks stunning but also drives consumer engagement and loyalty. Use this guide and its best practices as a roadmap to craft compelling, on‑brand color palettes that set your products apart.

FAQs of packaging color

How many colors should I use on a single bag?

When deciding on a color scheme for one bag, strike harmony between visual appeal and simplicity. Starting with a basic color that captures the core of your brand, this will be the color that anchors every design and shows across your whole product range. Then, without sacrificing your basic identity, add a secondary color to support hierarchy and set apart variations or variants. At last, add up to two accent colors to draw attention to important details as flavor names, weight markers, or sustainability labels. While too few colors would leave your design seeming flat, too many would overload the eye and dilute brand awareness. A 2–4 color approach guarantees clarity and impact, therefore guiding the customer’s attention to the most crucial information.

Can eco‑inks match the vibrancy of conventional inks?

Eco‑friendly inks—such as water‑based, soy‑based, or vegetable‑derived pigments—have made significant strides in color performance. In most cases, they can approach the brightness and saturation of petroleum‑based alternatives, but subtle differences remain. Because these inks often have a slightly more translucent quality, you may need to tweak hue values (for example, choose a slightly more vivid green or a deeper red) to compensate for reduced opacity. Always run material‑specific proofs—ideally on your exact substrate and with your chosen barrier coatings—to verify how the ink sits on the surface. These test prints will allow you to adjust ink load, overprint techniques, and spot varnishes to achieve the desired level of vibrancy.

How do I choose colors for different flavor variants?

Establish a consistent accent logic that ties each flavor to a familiar color cue, helping consumers quickly identify their preferred option. For instance:

Citrus or tropical flavors → bright yellows, oranges, or lime greens

Berry or red fruit flavors → rich reds, magentas, or plums

Nutty or earthy profiles → warm browns, muted golds, or olive tones

Always keep your primary brand color as the backdrop or base layer so that, regardless of accent, the bag remains unmistakably yours. This system lets customers scan a lineup and immediately associate each accent hue with a flavor category, while the brand’s hallmark color maintains cohesion across the shelf.