Plastic pouches, a prevalent form of plastic packaging, are deeply ingrained in our daily routines. Among them, coffee pouches, especially drip coffee pouches, have become a staple for coffee enthusiasts. These pouches keep coffee beans fresh, preserving their rich aroma and flavor. Food packaging pouches safeguard our meals during takeout and storage, and pet food pouches are crucial for keeping pet food dry and palatable.

The global usage of these plastic pouches, including coffee pouches, which are consumed in large quantities daily, is staggering. This widespread use raises a pivotal question: Are plastic bags recyclable? Given the growing environmental pollution, with plastic waste overwhelming landfills and oceans, answering this question is essential. It is directly linked to the pursuit of sustainable waste management. Discovering effective recycling methods for these pouches, especially the commonly used coffee pouches, can significantly reduce our environmental impact.

Plastic Bag Materials

Common Types of Plastics in Bags

Polyethylene (PE) is a dominant material in plastic bags. High-Density Polyethylene (HDPE) is known for its remarkable strength and durability. Bags made from HDPE can withstand significant weight without tearing, making them suitable for carrying heavy items like bottled drinks or large groceries. Its stiffness also gives it a certain form-holding capacity. On the other hand, Low-Density Polyethylene (LDPE) offers excellent flexibility. LDPE – made bags are soft and pliable, which is ideal for applications where the bag needs to be easily manipulated, such as sandwich bags or lightweight produce bags.

Polypropylene (PP) is used in some specialized plastic bags. It has high heat resistance, which makes it suitable for applications where the bag may be exposed to elevated temperatures, like certain food packaging that undergoes heat-sealing processes. PP also has good chemical resistance, protecting the contents from potential chemical reactions.

Additives and Their Effects

Plastic bags often contain various additives. Colorants are added to give bags different hues, which can be for branding or aesthetic purposes. However, certain colorants may complicate the recycling process as they can affect the color of the recycled plastic, limiting its use in applications where a specific color is required. Antioxidants are used to prevent the plastic from degrading due to oxidation, extending the bag’s lifespan.

But during recycling, antioxidants might interfere with the melting and reprocessing of the plastic. Anti-slip agents are added to some bags to prevent them from sliding off surfaces. These additives can change the surface properties of the plastic, making it harder to clean and sort during recycling, thus potentially reducing the overall recyclability of the plastic bags.

Are Plastic Bags Recyclable?

General Recycling Infrastructure

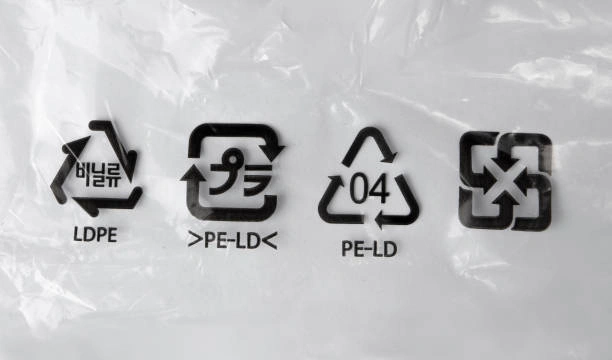

At recycling facilities, the journey of plastic waste begins with the sorting stage. Workers or automated sorting machines use resin identification codes (RICs), which are small numbers inside a triangular chasing arrows symbol found on plastic items. For plastic bags, the most common RICs are 2 for HDPE and 4 for LDPE. By scanning or manually checking these codes, different types of plastics are separated.

Once sorted, the plastic bags are then shredded into small pieces. This shredding makes the plastic more manageable for the subsequent steps. After shredding, the plastic pieces are washed to remove any contaminants such as dirt, food residues, or adhesives.

Following the cleaning process, the plastic is melted in large furnaces. The temperature is carefully controlled according to the type of plastic. For example, HDPE has a higher melting point compared to LDPE. Once melted, the plastic can be remolded into various shapes. This could involve extruding the molten plastic through a die to create plastic pellets, which are the building blocks for manufacturing new plastic products. These pellets can be used to make new plastic bags, containers, or other plastic items.

Challenges in Recycling Plastic Bags

One of the major challenges in recycling plastic bags is entanglement. Plastic bags are lightweight and flexible, which causes them to get caught in the moving parts of recycling machinery, like conveyor belts, sorting drums, and shredders. When this happens, it can disrupt the entire recycling process, leading to operational issues. Workers may need to stop the machines to manually untangle the bags, which results in downtime for the recycling plant. This not only reduces the overall efficiency of the recycling process but also increases labor costs.

Another significant problem is the low-quality output. Recycled plastic bags often yield a lower-grade recycled plastic. The repeated melting and reprocessing during recycling can degrade the polymer chains in the plastic. Additionally, the presence of additives and contaminants that are difficult to completely remove can also affect the quality of the recycled plastic. This lower-quality plastic may not be suitable for applications that require high-strength or clear-quality plastic, such as food packaging. Instead, it may be limited to uses like making lower-grade plastic lumber, which has less demanding quality requirements.

Factors Affecting the Recyclability of Plastic Bags

Contamination

Food residues and dirt severely impact plastic bag recycling. In recycling plants, plastic waste is processed in batches. A single soiled bag, say with sandwich crumbs or greasy food, can smear contaminants on other plastics during sorting, shredding, and washing. This cross-contamination renders the whole batch unsuitable, leading to rejection and landfill disposal.

Consumers can help. After using a food-related plastic bag, empty it and shake out crumbs. For sticky residues, a quick water rinse works. Using mild detergent and drying can further enhance recyclability.

Bag Design and Thickness

Complex bag designs with handles, zippers, or multiple layers are hard to recycle. Handles made of different materials need separation, adding labor, or requiring special machinery. Zippers can damage shredders and contaminate the plastic melt. Multiple-layer bags are difficult to disassemble due to different melting points and chemical properties.

Bag thickness matters too. Thinner bags, though lightweight and cost-effective, tear easily during sorting and shredding, producing hard-to-process pieces. Thicker bags are more robust but demand more energy for melting and re-processing.

How Do I Know if a Plastic Bag Can Be Recycled?

To determine if a plastic bag is recyclable, start by checking for the resin identification code. Look for a small triangle with a number (usually 2 for HDPE or 4 for LDPE) inside. Bags made of these common polyethylene materials are more likely to be recyclable. However, as mentioned, even with the right code, contamination can be a deal-breaker. If the bag has food residues, like sandwich crumbs or greasy stains, it may not be recyclable. Cleanliness is key; a bag that’s been thoroughly emptied, shaken to remove loose particles, and rinsed if necessary stands a better chance.

The bag’s design also plays a role. Simple, single-layer bags without handles or zippers are generally easier to recycle. Complex designs with added features often require special recycling processes. Additionally, consider the thickness. Thinner bags, while more prone to tearing during recycling, are more common in curbside recycling programs compared to very thick or multi-layer bags. By evaluating these aspects – code, cleanliness, design, and thickness – you can make a more informed decision on a plastic bag’s recyclability.

Conclusion

Currently, recycling plastic bags is difficult due to entanglement in machinery and the need for specialized processes. However, finding solutions is crucial to reduce plastic waste in landfills and oceans.

For consumers, reducing plastic bag use is a great start.

Opting for reusable bags in grocery stores or bringing your own containers for takeout can cut down on single-use plastic. When plastic bags are necessary, ensure they are clean before recycling. Empty out food residues, shake off crumbs, and rinse if needed. By taking these steps, consumers can contribute to a more sustainable future.