In today’s era, the concept of environmental protection is like a strong east wind sweeping across all fields around the world, and the packaging industry is inevitably involved in this wave of change. Traditional packaging, especially plastic packaging, brings convenience while also bringing a heavy burden to the environment. Plastic waste piles up like mountains and is difficult to degrade in the natural environment, causing great damage to the soil, water sources, and marine ecosystems. According to statistics, millions of tons of plastic waste flow into the ocean every year, threatening the survival of countless marine species.

Against this background, biodegradable food packaging came into being and became a key force for change in the packaging industry. Like a ray of light in the dark, it brings hope for solving the problem of packaging pollution. Its emergence is not only a technological innovation, but also a practice of the environmental protection concept. It represents the future development direction of the packaging industry, has aroused widespread attention from all walks of life, and has attracted many researchers, enterprises, and consumers to join in and explore the path of sustainable development together.

What Does Biodegradable Mean?

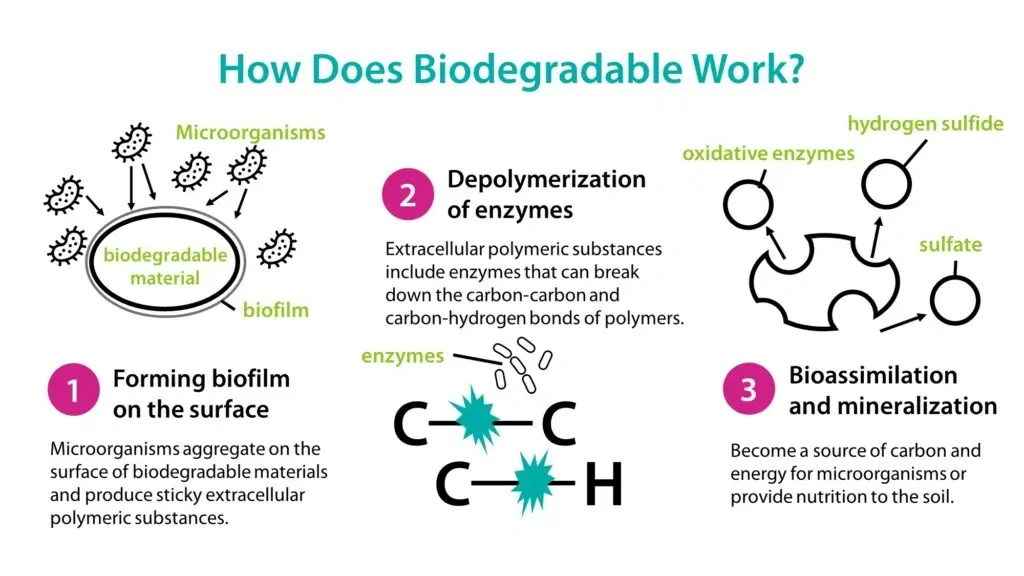

From a scientific point of view, biodegradation refers to the process in which materials gradually decompose and transform into small molecules in the natural environment, relying on the action of microorganisms such as bacteria, fungi, and algae, and finally integrate into the natural ecosystem. This process is like a magical process of nature, which cleverly transforms the original material so that it no longer burdens the environment.

Take common biodegradable packaging materials as an example. In the soil, water, and other environments, microorganisms will secrete various enzymes, which are like tiny “scissors” that can cut the polymer chains in the packaging materials. For example, in the soil, the amylase secreted by bacteria can act on starch-based packaging materials and decompose them into small molecules such as glucose. These small molecules will then be further absorbed and utilized by microorganisms, and after a series of complex metabolic activities, they will eventually be converted into water, carbon dioxide, and biomass, and return to the natural cycle.

Common Biodegradable Materials

In the pursuit of a sustainable future, biodegradable materials have emerged as a promising solution to the global waste issue. These materials can decompose naturally, reducing environmental pollution.

Starch-Based Polymers

One common biodegradable material is starch-based polymers. Derived mainly from corn, wheat, or potatoes, starch can be processed into polymers. They are often used in food packaging due to their ability to form films. However, their high sensitivity to moisture is a drawback. For example, starch-based food containers may become soggy if exposed to humidity for too long.

Cellulose-Based Materials

Cellulose-based materials are another type. Cellulose, abundant in plant cell walls, can be obtained from wood pulp or cotton. Cellulose-acetate films, for instance, are used in cigarette wrapping and some food packaging. They offer good strength and moisture resistance, making them suitable for various applications.

Polyhydroxyalkanoates (PHA)

Polyhydroxyalkanoates (PHA) are synthesized by microorganisms. PHA has excellent biodegradability in different environments, including soil and water. It is used in medical applications like dissolvable sutures because of its biocompatibility. However, its high production cost limits wider use.

Polylactic Acid (PLA)

Polylactic acid (PLA), made from renewable resources such as corn starch or sugarcane, is also popular. PLA can be processed like traditional plastics and is used in disposable cutlery and 3D-printing filaments. Although it has good mechanical properties, its slow degradation rate in anaerobic conditions is a concern.

These biodegradable materials show great potential in reducing our ecological footprint, but continuous research is needed to overcome their limitations and promote their wider adoption.

Kraft paper is one of the most common biodegradable materials used to package roasted coffee. It is produced through the kraft process. Wood is chemically converted into wood pulp. After the lignin is separated from the cellulose fibers in the wood, the cellulose pulp is filtered and then made into kraft paper.

While it is strong and environmentally friendly, it is not as effective as other materials at preserving freshness. Therefore, it tends to be favored by specialty coffee roasters who distribute coffee to consumers in small batches. At BNPACK, we offer 100% biodegradable and compostable kraft paper for coffee packaging.

Disposing Of Biodegradable Packaging

As the use of biodegradable packaging continues to grow, it is important to understand its proper disposal methods. Made from materials such as starch-based polymers, cellulose-based materials, polyhydroxyalkanoates (PHA), and polylactic acid (PLA), biodegradable packaging is designed to decompose naturally.

One of the main disposal methods is composting. In a composting environment, microorganisms break down biodegradable packaging into nutrient-rich soil amendments. For example, starch-based food containers can be added to a backyard compost pile. Over time, they will decompose, making the compost rich in organic matter. Municipal composting facilities also play an important role. They can handle a large amount of biodegradable waste, including packaging materials. However, not all biodegradable packaging is suitable for home composting. Some materials, such as some types of PHA-based packaging, may require industrial composting conditions with specific temperature and humidity levels.

Another option is landfilling, although it is not the most ideal. In a landfill, biodegradable packaging can break down, reducing the long-term waste burden. But the anaerobic conditions of a landfill can slow the degradation process, especially for materials such as PLA. Additionally, if landfills are not properly managed, decomposition may produce methane, a potent greenhouse gas.

In some cases, it is also possible to recycle biodegradable packaging. For example, cellulose-based materials such as kraft paper can often be recycled like regular paper. However, recycling facilities need to be able to distinguish between biodegradable and non-biodegradable materials to ensure effective recycling.

In summary, while biodegradable packaging has tremendous environmental benefits, proper disposal is key. Increased public awareness and improved waste management infrastructure are needed to realize the full potential of these materials in reducing their environmental footprint.

How Long Does It Take for Biodegradable Packaging to Decompose?

There are many different factors in the decomposition time of biodegradable packaging, and there are huge differences. For example, if you use normal packaging with a biodegradable thin film based on starch powder, it can be easily decomposed under the best compost conditions. During well-managed composting, with the appropriate amount of heat and humidity level, the compost can be decomposed within a month.

However, the current demand for oxidative fatty acid (PHA) materials will increase over time. In an industrial compost environment, PHA can be packaged and decomposed within approximately 3 to 6 months. In the ideal environment, where the land is filled and buried, etc., the situation is such that the leadership position, the disassembly process, and the heavy arrogance.

A small amount of lactic acid (PLA) is a biodegradable plastic that can be completely decomposed in the field for several years. Cowskin paper is a kind of biodegradable material, which usually decomposes in soil or compost within a month, but it is also influenced by factors such as humidity, the presence of certain microorganisms, etc.

The Benefits Of Biodegradable Packaging For Roasters

For coffee roasters, biodegradable packaging offers several advantages. From an environmental perspective, it’s a win-win. By using biodegradable materials such as kraft paper or starch-based films, roasters reduce their contribution to landfills. These materials break down naturally, minimizing long-term environmental impact. This not only helps protect the planet, but also fits in with consumers’ growing preference for sustainable products.

From a brand-building perspective, biodegradable packaging sets roasters apart. It demonstrates a commitment to environmental responsibility and can attract environmentally conscious customers. In a competitive market, this can boost brand image and customer loyalty. For example, roasters that use 100% biodegradable and compostable packaging send a clear message of sustainability.

Biodegradable packaging often has good moisture and odor resistance, which is essential for preserving coffee freshness. Although it may be less efficient in some ways compared to traditional packaging, its ability to keep coffee quality intact for a reasonable period of time while being environmentally friendly makes it an attractive option for roasters looking to balance product protection and environmental concerns.

Conclusion

For more information on our range of biodegradable coffee packaging solutions, contact our team, BNPACK. Stay updated about all our products & services by signing up to our free newsletter.